GRAIN STORAGE SYSTEMS

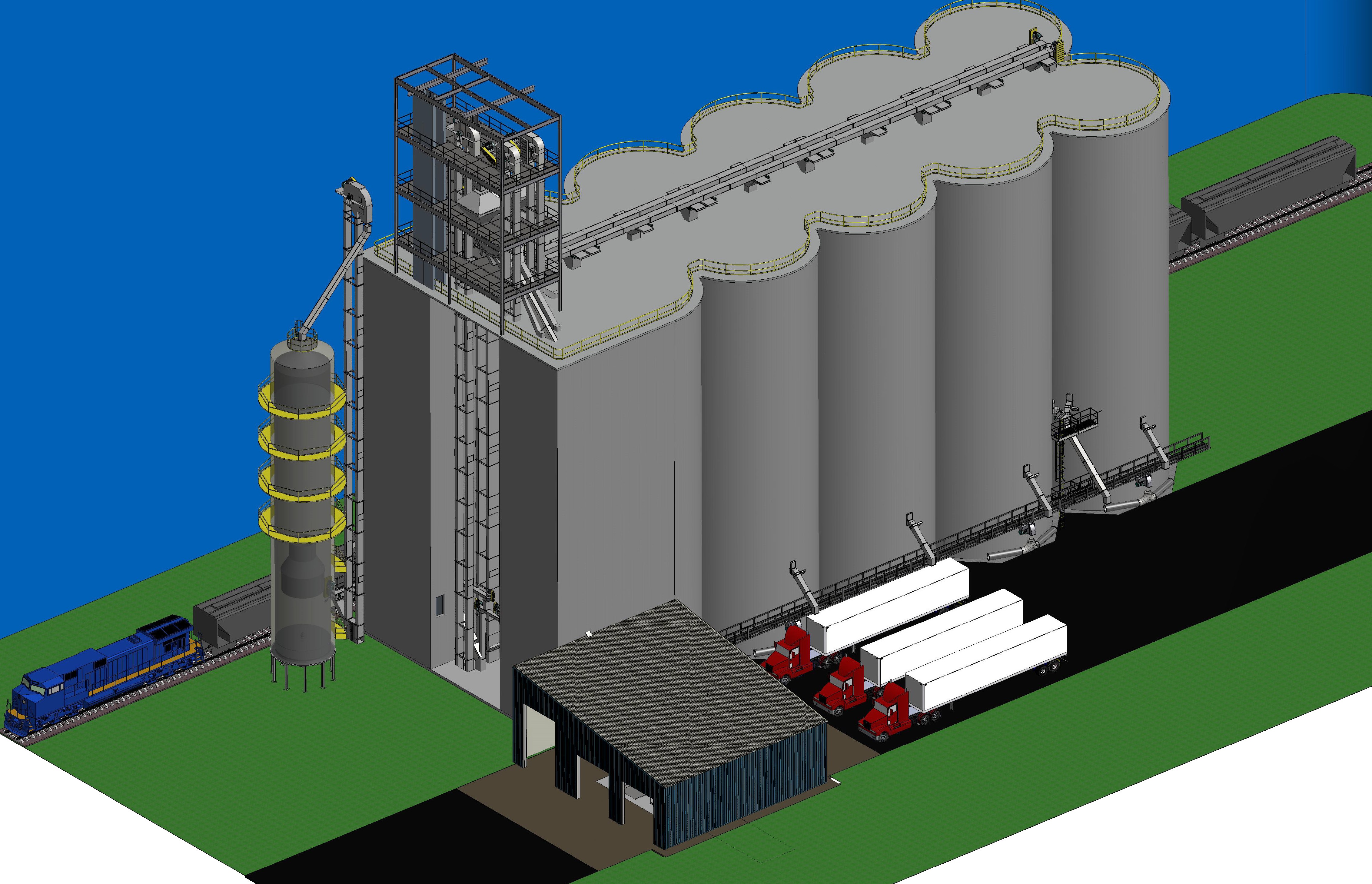

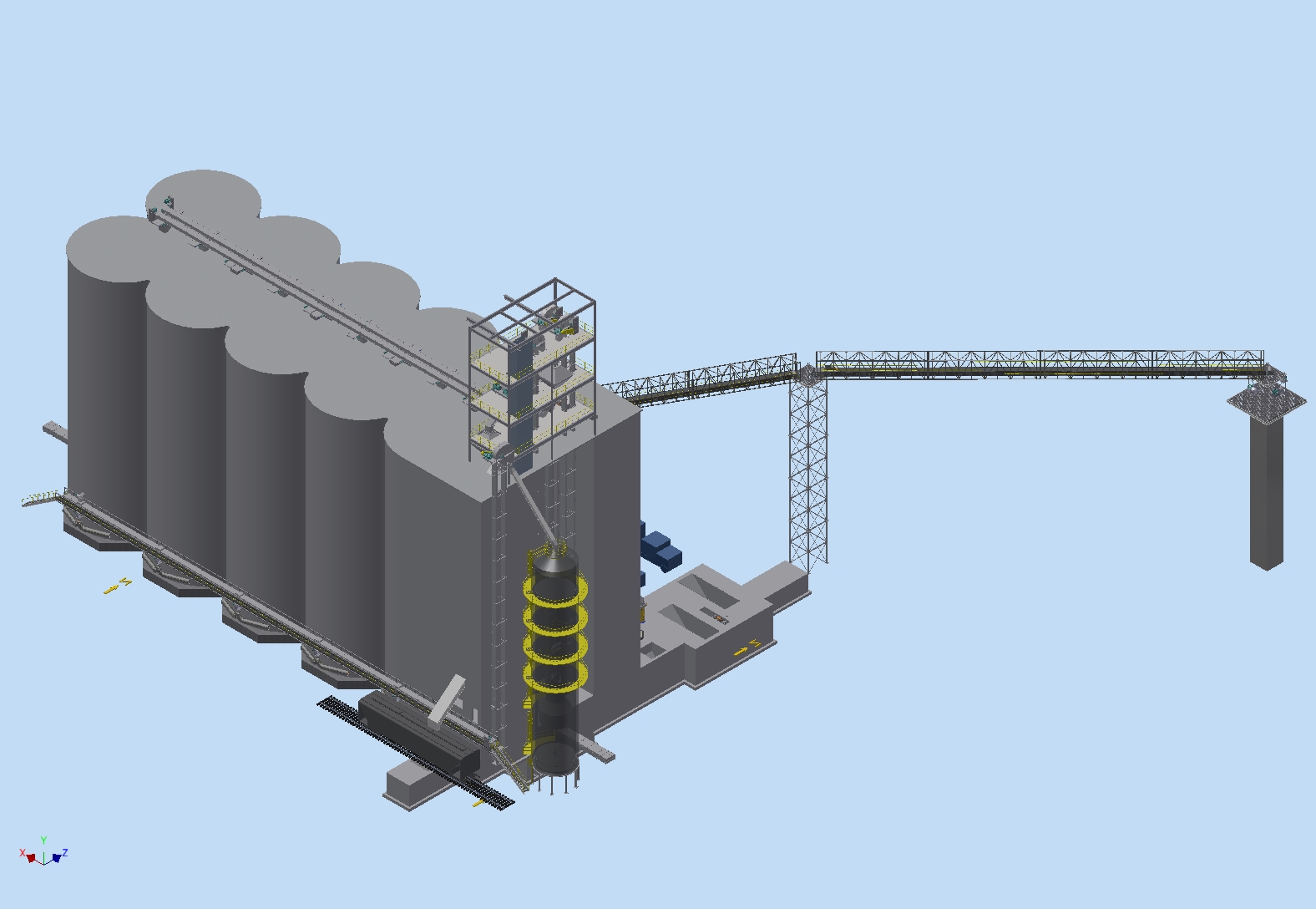

Hi-Speed Rail Systems

My first hi-speed rail system was in 1985 for Billings Grain Terminal, Billings, Montana. It was designed for 54-rail cars using 20,000 BPH equipment. Charley Riley, Riley Equipment said it was his first 20K BPH bucket elevator.

GRAIN STORAGE SYSTEMS

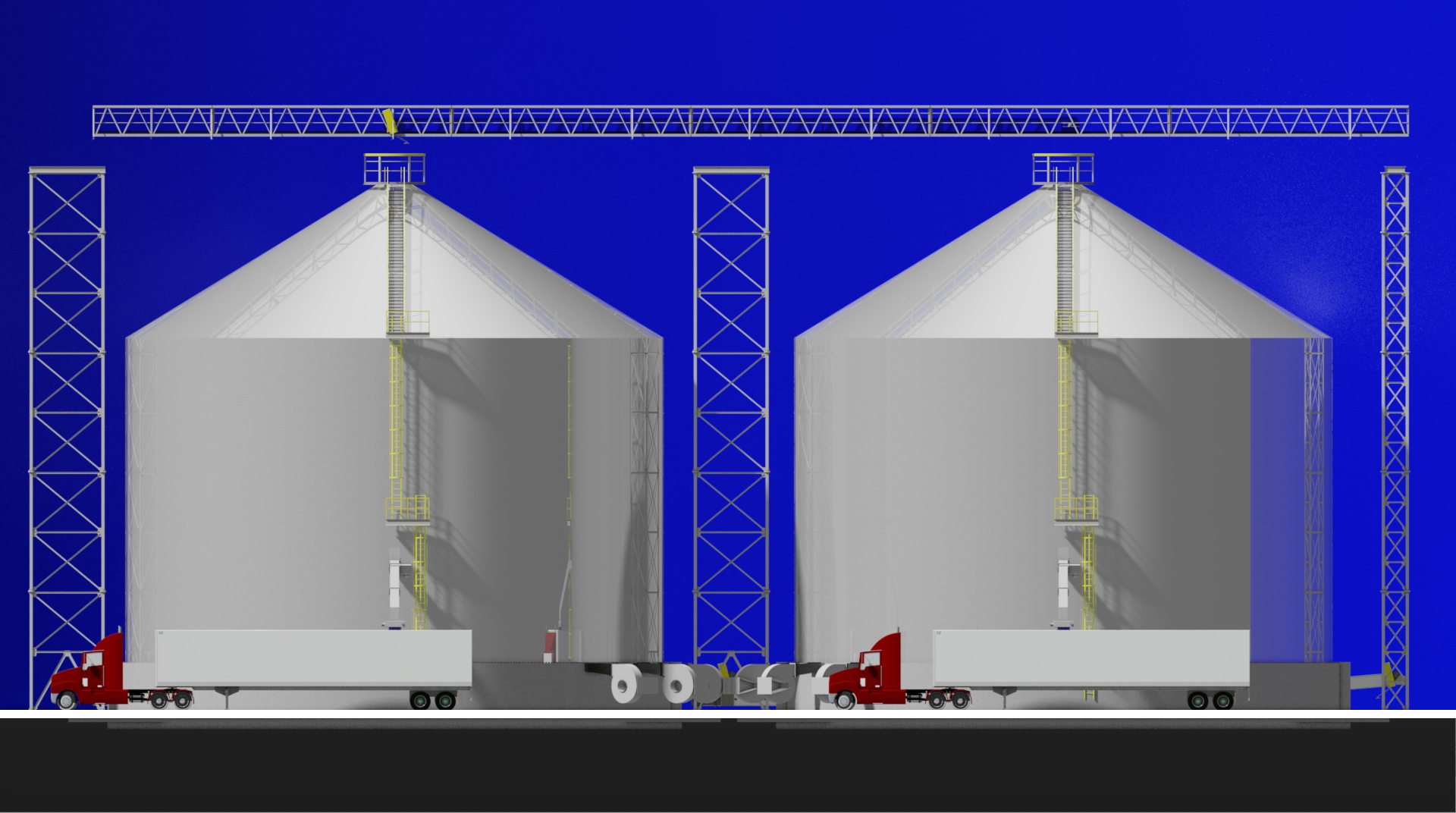

2.66" & 4.00" Corrugated Galvanized Steel Bin Storage Systems

GRAIN STORAGE SYSTEMS

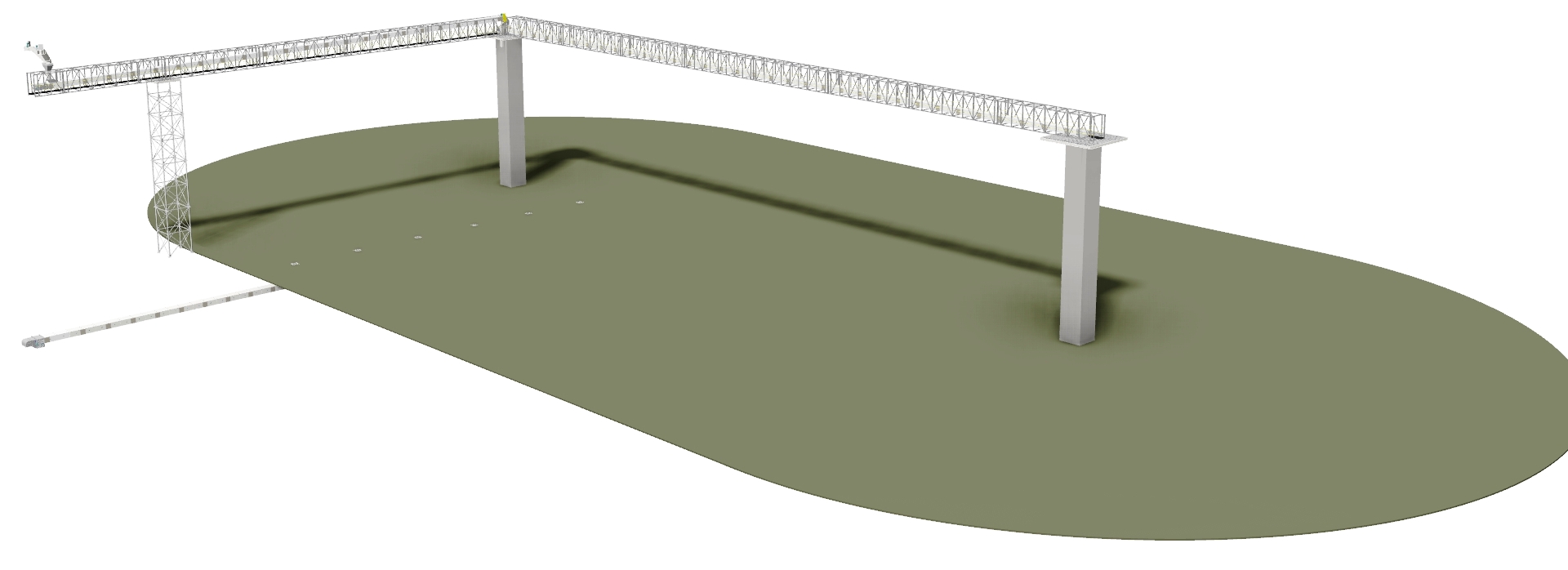

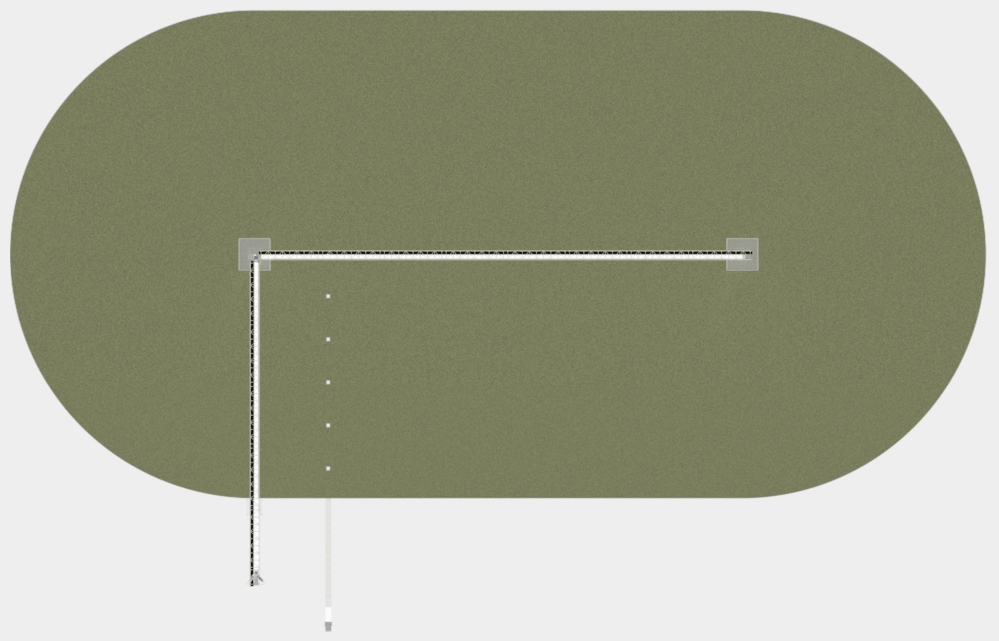

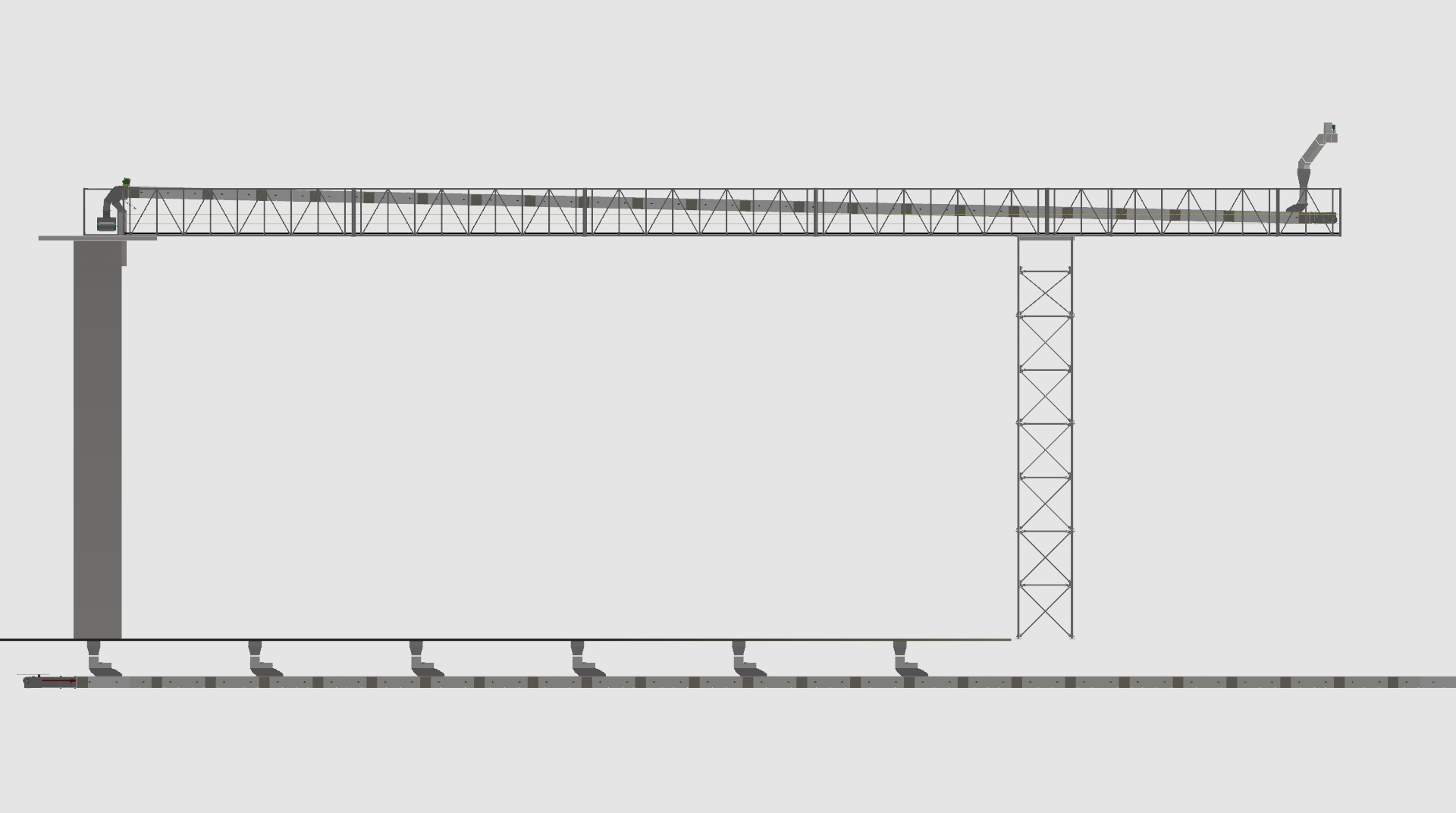

Temporary Bunker Grain Storage

GRAIN STORAGE SYSTEMS

Dwight Kinzer, dba Process Equipment & Design LLC specializes in the preparation of Process Flow Diagrams, Master Planning, 3D and 2D CAD Designs & Layouts, and Program Management of Grain Cleaning, Handling, and Storage Systems.

Clients are guaranteed personalized service because Dwight Kinzer does all of the work.

sales@grainfeedseed.com 701-388-3645

Experience with USA and International Grain Handling & Storage Systems:

- Barley;

- Canola;

- Chickpeas;

- Commercial Grain Storage Systems;

- Corn;

- Ethanol Corn Storage Systems;

- Ethanol Dried Distillers Grains (DDG) Storage & Loadout;

- Green & Yellow Field Peas;

- Identity Preserved Segregated Storage;

- Lentils;

- On-Farm Grain Storage Systems; and

- Strategic Long-Term Grain Storage.

3D CAD, Design, and Engineering of Grain Systems:

- Aeration and Cooling of Stored Grains;

- Automation;

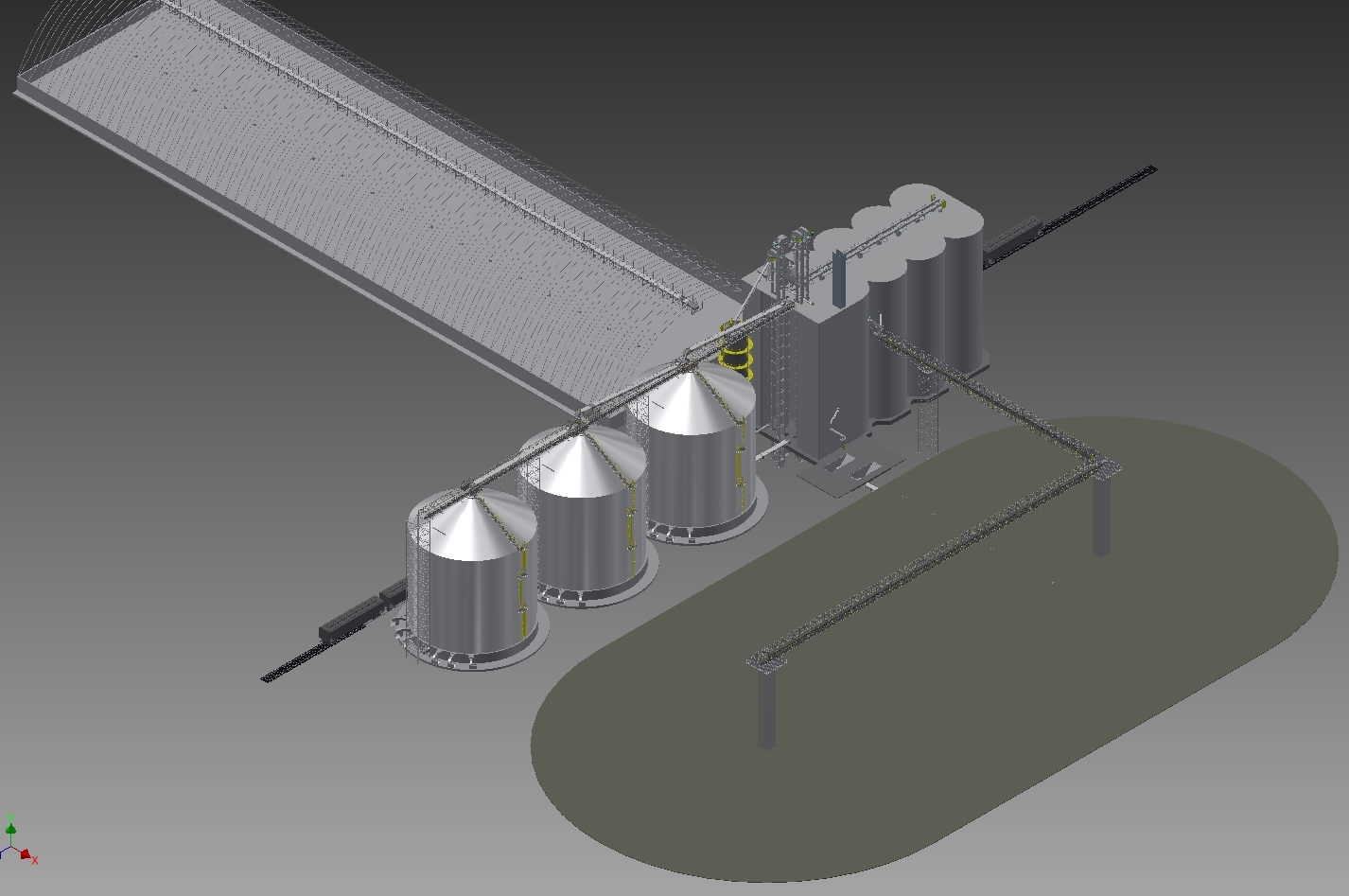

- Corrugated Galvanized Steel Grain Storage Bins;

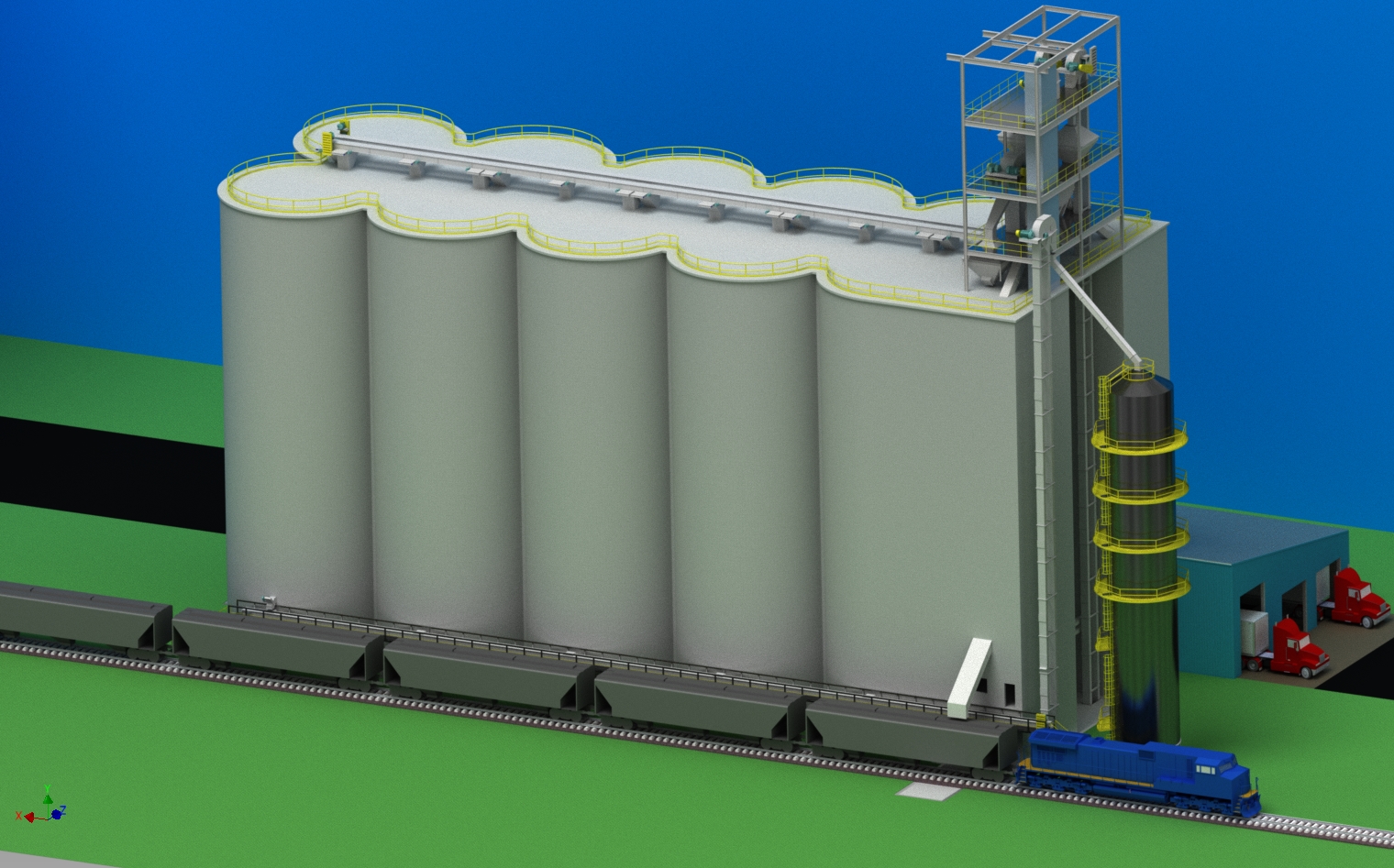

- Concrete Silos for Grain Storage;

- Grain Cleaning Systems;

- Grain Drying Systems;

- Ground Pile Grain Storage – Temporary Bunker;

- Hi-Speed Rail and Truck Receiving and Loadout Systems;

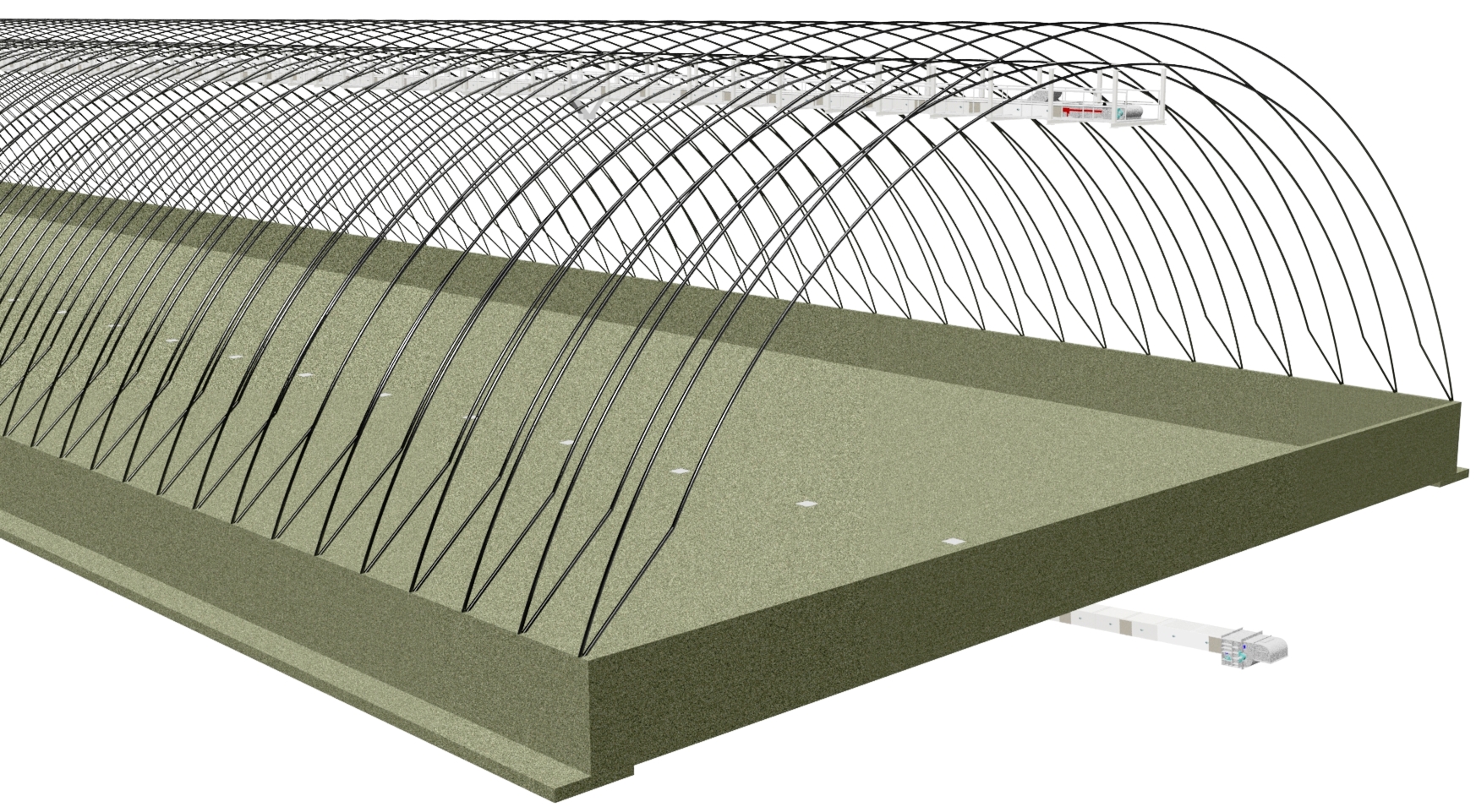

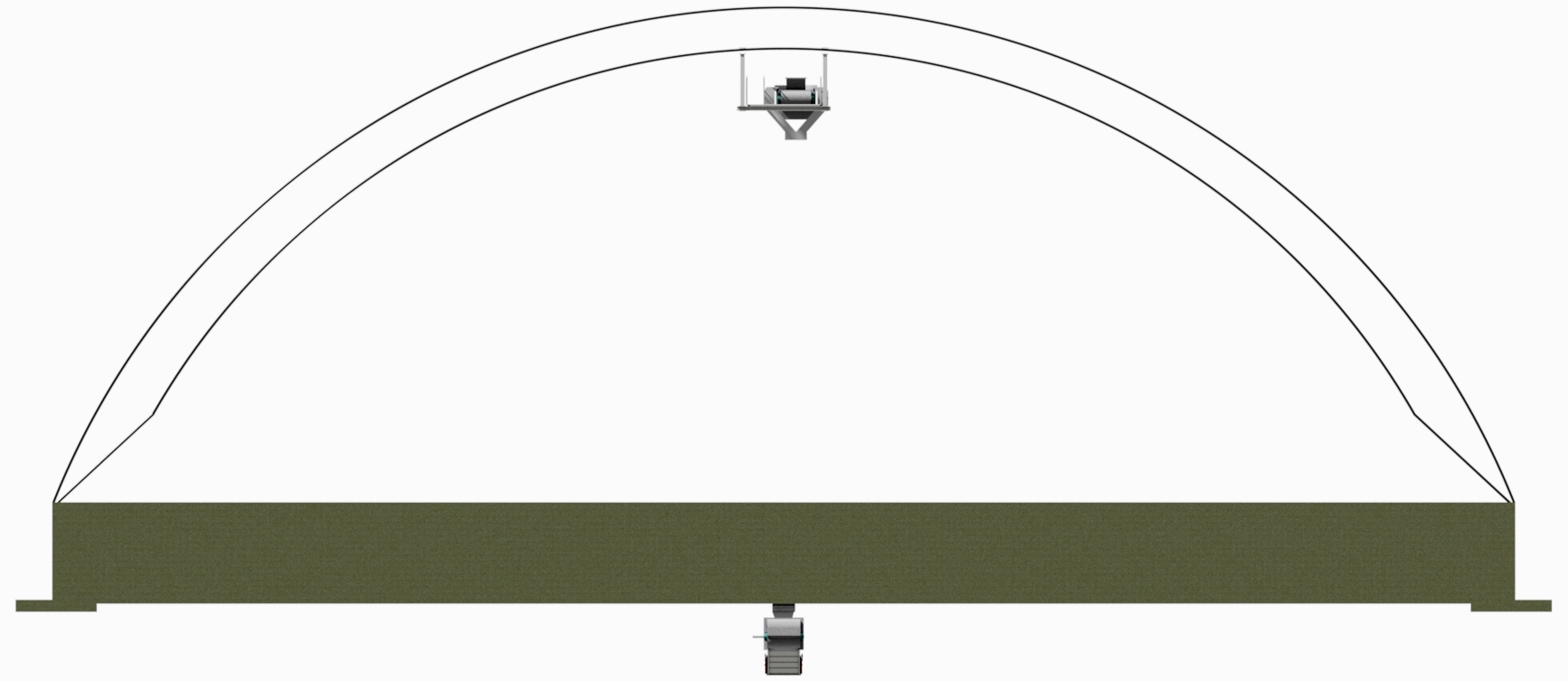

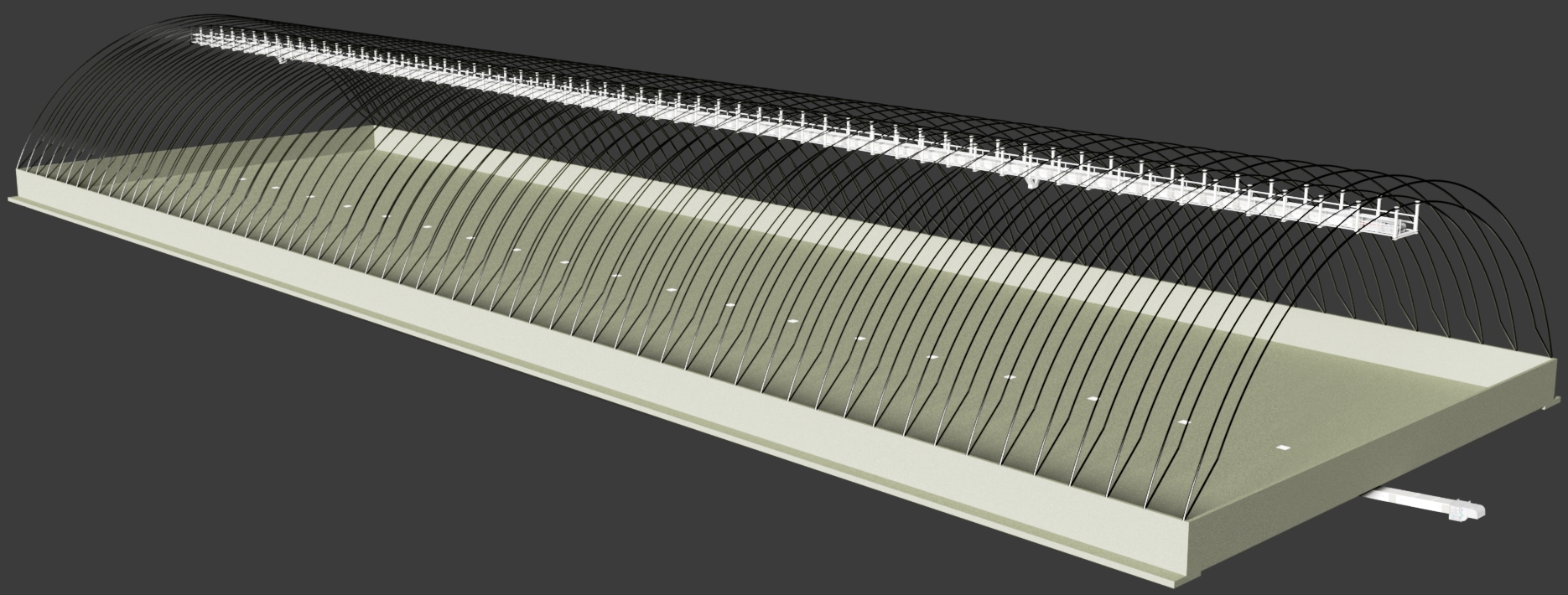

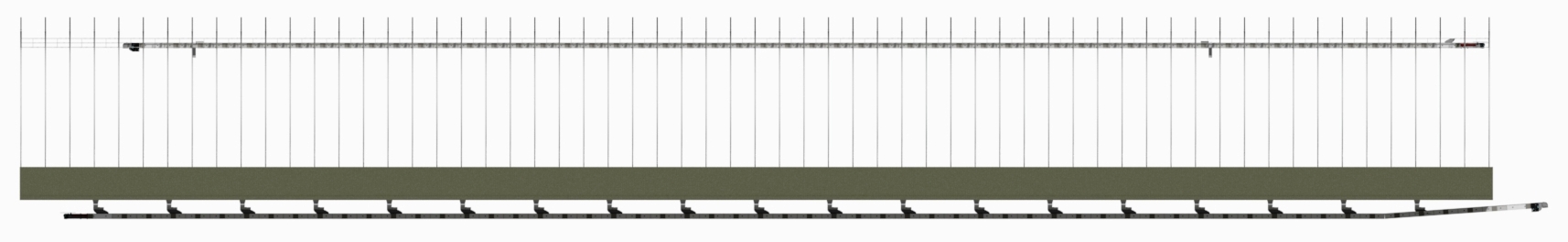

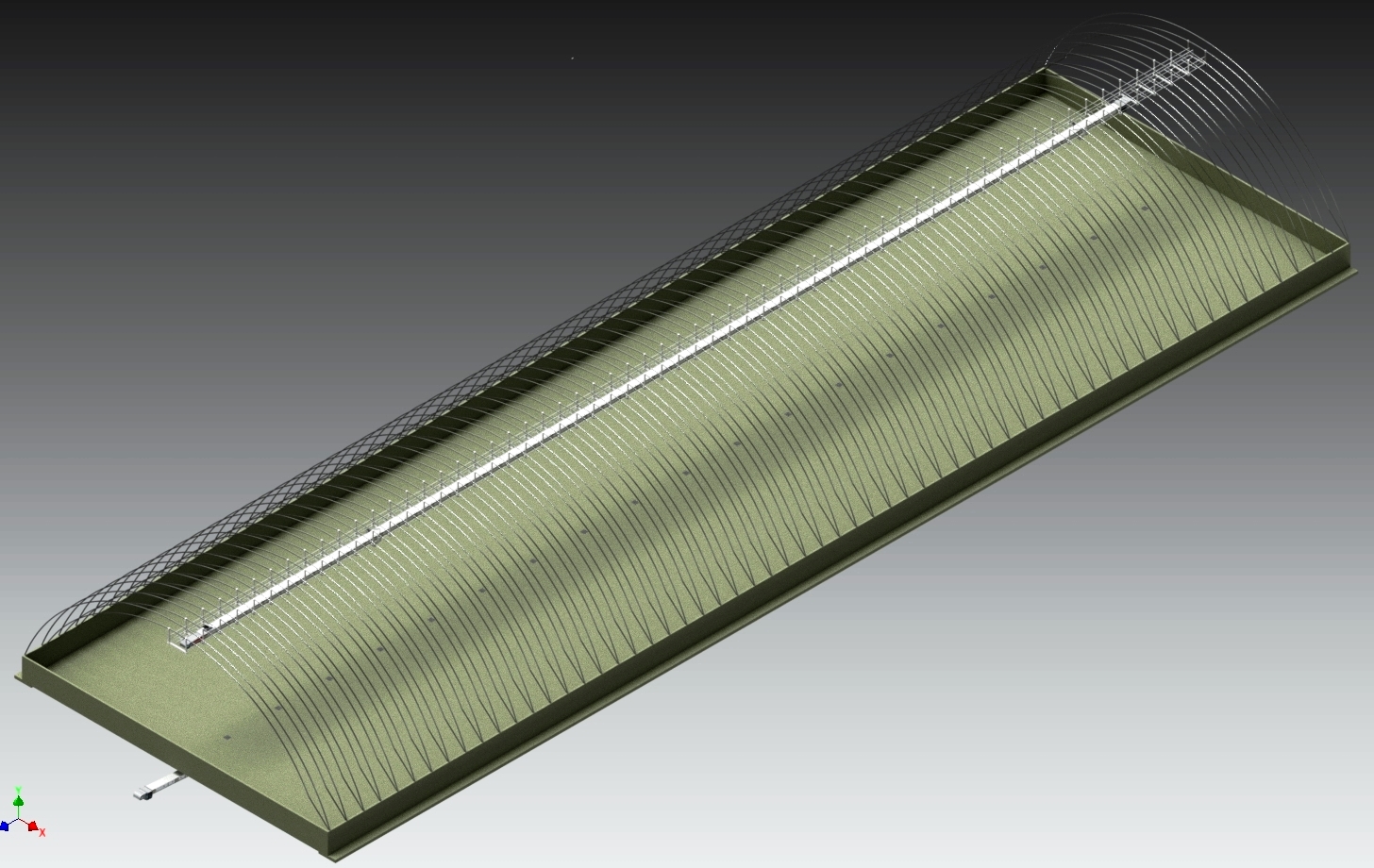

- Hoop Barn Grain Storage;

- Segregated Storage for Identity Preserved Commodities; and

- Strategic Grain Storage Systems.

GRAIN STORAGE SYSTEMS

Sioux Steel Hoop Grain Storage Buildings